The future of industry is the digital industry or the more aptly named Industry 4.0 involves things like Internet of Things (IoT), Machine Learning and Artificial Intelligence (AI). Industrial digitalization seeks to improve operational efficiency where companies seek to improve quality, speed, efficiency and reduce cost.

The road to digitalization revolves a lot around smart sensor or IoT. It is about connecting the unconnected. In our daily lives, the most evident is connecting humans especially through smartphones. We can easily share our location to send to our friends. Runners use a combination of smartwatch and smartphone to track their running achievements of time, location and distance.

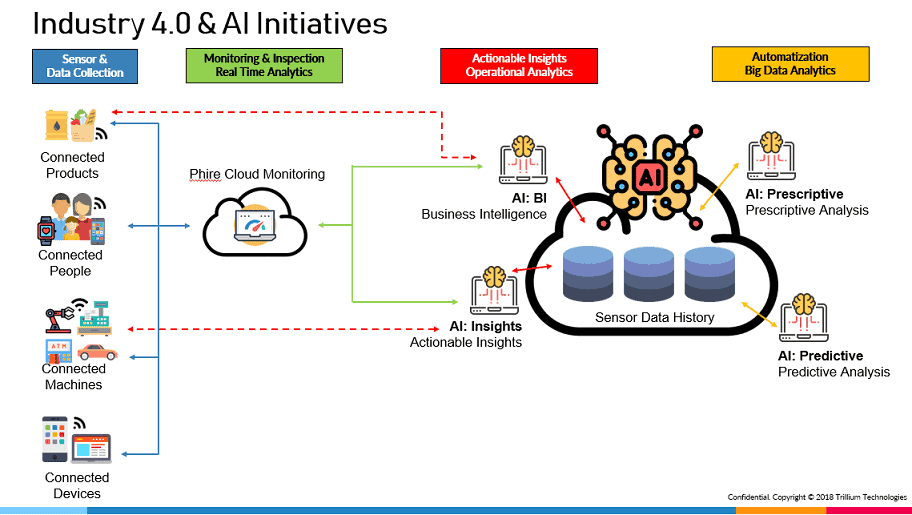

As shown in Image 1, Industry 4.0 or AI involves 4 different major parts – Data Collection, Real-time Monitoring and Inspection, Actionable Insights and finally Automatization.

At Trillium, we invite you to the journey to Industry 4.0 with our end-to end solution. We say we are on the journey because many people buy in the hype of IoT or AI. It is not the magic solution for all.

The first path begins with data. It starts with process digitalization and proper data collection. Based on Microsoft’s Asia Data Culture Study 2016, less than half of business leaders believe they have a full digital strategy in place today and even more needs to be done to develop a data culture. Data is at the front of it all. It is not just having any data, but proper, accurate and timely data.

Once businesses have the proper data, they can have real time analytics through active monitoring and inspection. We provide one of our customers in in a global automotive manufacturing company with the ability to replace human manual defect inspection of a finished goods using vision technologies and machine learning. Digitalization is not about replacing manpower. The key item is the data we are able to extract using vision technologies. We are not only able to provide defects identification, but also provide more in-depth data like classification, occurrence rate, severity rate, location, batch number, date and time produced, batch source and many more. These data are not new to the manufacturer. The difference is the speed and accuracy in which the data collected to be easily presented, digested and acted upon by the respective person in charge – actions which would normally take days or even weeks of manual gathering and fact checking.

Businesses can then have effective actionable insights to better manage and expect the future. Actionable insights can help businesses reduce costs, increase quality and efficiency and in turn provide more revenue streams. We provide our client in the water treatment industry with the ability monitor the debit of raw water vs processed water discharge, quality, pressure, temperature, turbidity, pH or chlorine of water using smart sensors. Previously these actions were done periodically through sample testing. With the available data from the smart sensors, this can be used to calculate the efficacy of the selected treatment process and ensure that the released amount of chemicals stay within permissible limits. The company in turn were able to reduce costs, increase water quality and increase the amount of processed water.

As businesses collect data, monitor data and act on the data based on insights, there will be extensive histories and patterns. This is where we rely on predictive analysis to predict trends and behavior patterns. We use historical data to provide and predict possible outcomes. In manufacturing industries, this will be used to predict and prevent potential issues such as machine break-down or reduce defective rate.

The holy grail of analytics is prescriptive analytics, the final step towards the automatization decision making of all things. Data collection and monitoring involves what happened and why did it happen. Predictive analytics answers the question of what will happen. The final phase of analytics gives businesses the answer of what should they do, finding the best course of action for a given situation. Predictive and especially prescriptive analysis are only as good as their data. While these analytics terms sound great on paper, we often remind businesses it all starts with good data culture. Bad and inaccurate data will result in bad prediction of what business decisions and insights.

At Trillium, our passion is shaping and helping businesses with technology. As you embark on this journey to Industry 4.0 with us, we will give you a single magic formula for solve all your problems. What you will get is a real journey that will truly transform your businesses. Are you ready to take the first step?